RAW MATERIAL : PIPES | TUBES | ANGLES | FLATS | CHANNELS | BEAMS

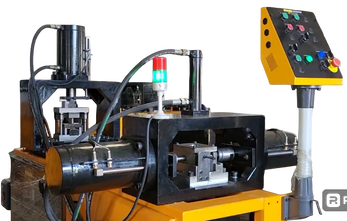

Capable of producing ready-to-weld parts in a 3-step process, these units can automatically Punch, Notch & Bend structural channels without moving the material throughout the shop-floor onto dedicated machinery for each feature.

Can be programmed to punch multiple sides of structural steel in one go, without actually rotating and re processing all over again. All unnecessary engineering steps and supplementary procedures can be eliminated entirely from the course of manufacturing. End-to-end fabrication can be carried out 3-4 times faster than conventional methods while 30-40% of decrease in operating costs is guaranteed.

CUSTOMIZATION : As per your drawings and part families, we suggest the most cost efficient way - we justify & advice on customized configurations like adding punching / drilling / cutting units as the projects demand.

ADDITIONAL ATTACHMENTS : Movable punching stations, Movable notching stations, Foot switch, CNC Gauge, adjustable gauges for positioning.