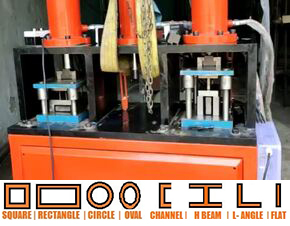

RAW MATERIAL : PIPES | ANGLES | CHANNEL | BEAMS | ALUMINIUM PROFILES | PURLINS | STRIPS | SHEETS | PLATES

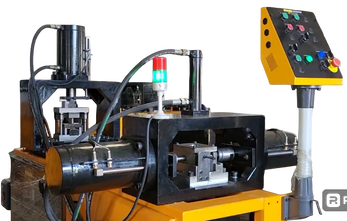

Automatically perform multiple operations like punch, holes, slots, cutting, notches, shear, stamp, draw, curl & cut long pieces of structural profiles with a single button click. Without moving the raw material throughout the shop-floor onto dedicated machinery, these machines are capable of producing ready-to-use parts in a uni-step process. These machines are designed as per the part drawing or part drawings family and can deliver very high productivity at a minimal running cost.

CUSTOMIZATION : As per your drawings and part families, we suggest the most cost efficient way - we justify & advice on customized configurations like using saw/shear/plasma cutting or attached punching and drilling units as the shop-floor projects demand.

ADDITIONAL ATTACHMENTS : Material auto loading / handling system, marking and engraving (Part numbering, QR, Layout instructions).

VARIANTS AVAILABLE : 2 / 3 / 4 / 5 STATION